air permeability test composite|air permeability test for fabric : services The determination of airflow resistivity based on the permeability coefficient is carried out via two approaches, that is, the direct method and the . Resultado da Play Agent Destiny at LeoVegas Casino today! It's one of many casino games available including slots, table games and live dealer games.

{plog:ftitle_list}

5 de dez. de 2023 · A subjective list of the 10 best Pokemon games across the generations, based on various criteria such as story, graphics, features, and nostalgia. Find out why .

how to calculate air permeability

The determination of airflow resistivity based on the permeability coefficient is carried out via two approaches, that is, the direct method and the .

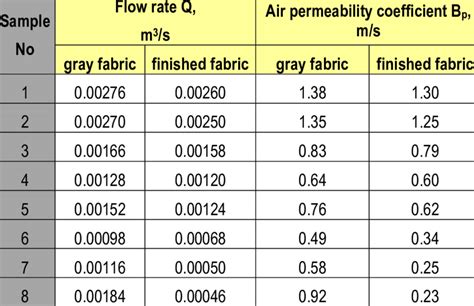

wetted and void-free composite production depends on the accurate air permeability characterization of reinforcement fabric stacks [2]. In this study, air permeability of single-, . In this study, air permeability of sing le-, double-, and triple-layer randomly oriented glass fiber. nonwoven fabrics were measured from both . One of the most critical properties which strongly affect processing time and porosities in the final composite part is the reinforcement permeability, which depends both .

general tools pin pad moisture meter

fabric air permeability chart

The guide clarifies the relationship between air permeability and breathability, dispelling misconceptions and comparing testing methods. It provides a step-by-step approach to conducting testing, interpreting results, and showcasing .

The air permeability and tensile strength tests were carried out and the fracture morphology was observed. The results showed that the GPPs with low porosity not only had .Air permeability is defined as velocity of an air flow passing perpendicularly through a test specimen under specified conditions of test area, pressure drop and time (BS 3424-16-1995). .The Frazier Air Permeability Tester is the worldwide defacto standard air permeability testing instrument for quality control, research, development, performance and purchase specifications. This instrument does an . The prepared PBAT/hemp@SiO 2 -PVSQ composite membranes showed excellent tensile strength with high moisture permeability, good waterproof and water contact .

To evaluate the effect of AMP composite concentration on the air permeability of device, the water vapor permeation test rate (WVTR) was measured at each condition 35,36,37, including the opening .

From this rate of air flow, the air permeability of the fabric is determined. Please email [email protected] or call (304) 547-5800 for information regarding test procedures, specimen size, pricing or any other ASTM D737 questions you may have. The features of an air permeability test device: Circular sample holder: The circular sample holder must have a central aperture which can give the opportunity to the experiment in an area of, or. Tools for the holders: That . This process provides a new industrial production method for the composite. Author contributions. Chaozhong Li researched the literature, fabricated the gradient porous plates (GPPs), conducted air permeability test and tensile test, observed the samples to get SEM images, and wrote the original draft preparation.

All permeability testing was done at ambient temperature. a. Nitrogen Versus Hydrogen as Permeant. To better understand how the results from the nitrogen permeability testing in this report may relate to the composite feedline hydrogen permeability, an examination of the important molecular constants of the permeation gasses is in order. Reinforced anticorrosive composite coating with mesh-brick structures and excellent air permeability on concrete. Author links open overlay panel Bing Yin, Fangyu Fan . abrasion resistance, and water vapor permeability (WVP) test. The results show that the coating with “mesh-brick” structures can significantly improve the hydrophobicity .1. Composit_ Permeability Bcfgr¢ Thcrm0,1 Cycling. The permeability of the two types of composite specimens tested before thermal cycling are given in table 2. Note that the specimens had permeability values so low that essentially a measurement could not be made. Table 2. Permeability results of uncycled composite specimens. Specimen Number 2 3

general tools pin pinless moisture meter for water damage

Copper powder and copper wire mesh were used as raw materials, and porous copper powder/mesh plates were prepared by pressing, rolling, and vacuum sintering. The plate morphology was observed by scanning electron microscopy. The air permeability of the porous plates was tested according to Darcy’s law, and uniaxial tensile tests were carried out on the .

Note that the description of the breathability (Breathabil) and our conventional air permeability (air permeability) test data unit mm / s is different, the main test of air permeability is air, not water vapour, so waterproof and breathable in the air permeability refers to moisture permeability that is, water vapour transmission rate.

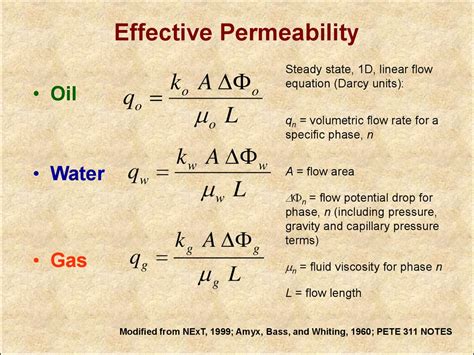

The following data obtained during a routine permeability test at 70 o F. Find the permeability. Flow rate = 2000 cc of air at 1 atm in 400 sec; Downstream pressure = 1 atm; Viscosity of air at test temperature = 0.02 cP; Core cross sectional area = 3 cm 2; Core length = 5 cm; Upstream Pressure = 1.75 atm; Solution

Uncontrolled Air Leakage. The key, is that this test measures uncontrolled air leakage. It is not concerned with trickle vents, extract fans or ventilation systems. Controlled ventilation sources will simply be taped up or sealed prior to testing. Therefore air permeability testing is looking for gaps and cracks in the fabric of the building.Composite Bag Filter Byung Hyun Park1, Sang Bum Kim1, Young Min Jo2, . Air Permeability of Test Filter Fig. 3 shows the measured pressure drop in relation to Fig. 1. SEM image of the prepared filter surface. 1032 Park et al., Aerosol and Air Quality Research, 12: 1030–1036, 2012Figure 3. Effect of test fabric face on air permeability Note: If the comparison circles intersect by an angle of more than 90 degrees, or if they are nested (as shown in the figure), the means are not significantly different. Table 4. Test fabric face versus air permeability report Test face mean, cm3/(cm2×s) sd cm3/(cm2×s) LL cm3/(cm2×s) UL b Air permeability test of the flexible piezoresistive sensor. c A photograph of the piezoresistive sensor worn on the skin (left) and a photograph of the skin after wearing it for 24 hours (right).

How to analyse ASTM air permeability test results on textiles? The ASTM air permeability test reports its results in either cubic meters per minute per square meter (m3/min/m2) or cubic feet per minute per square foot (cfm/ft2). Simply . Performance characterization showed that this three-layer composite nanofiber membrane had excellent air permeability and filtration efficiency, and the filtration efficiency of particles above PM 2.5 reached .

Membrane is a potential candidate to solve the challenge of air separation to meet the huge industrial demand of N2 or O2. In this contribution, four types of prominent metal organic frameworks (MOFs) with different pore sizes and series, including ZIF-8 (3.4 Å), ZIF-71 (4.2 Å), UiO-66 (6 Å) and MIL-53(Al) (16.3 Å) were synthesized, and used as a nanoporous filler . The results also suggest that the direct and extrapolation methods are applicable to assess airflow resistivity on an airflow velocity (or air permeability) test device. Moreover, the Ergun-type model is also applicable to determine the permeability coefficient and airflow resistivity of nonwoven materials. Due to the great potential of the resulted composite nanofibrous web to apply as a filter media in the face masks, air permeability is an important property that is investigated through air .

The air permeability test was conducted on five samples. The first test was performed on the sample acclimatized to ambient temperature, after which it was exposed to higher humidity in a dip basin. Wetting was performed via submersion of all of the test samples in water for 2 h and subsequent conditioning. The textile air permeability of U-10F is 0.109 cfm, lower than U-0F of textile air permeability. This result appears to be consistent with Fig. 4 SEM images of foam cells. The foam ratio of U-20F is 2.04, and the foam density is 0.72, which shows the 20% equivalent of PBA was added to the PTMEG, which would lead to the foam cell becoming . Standard Test Methods for Textile Air Permeability. A The square root of the variance component is used as the appropriate unit of measure for expressing variance performance, rather than the square of the variance.. 13.3 Nonwovens, Interlaboratory Test Data – An interlaboratory test was conducted in 1994 in which eight samples were randomly . CO2 permeability into PSF/PEG composite membranes containing 20 wt% PEG10000 is calculated 7.64 barrer (1 barrer = 10−10 cm3 (STP) cm/cm2 s cmHg). The ideal selectivity for CO2/N2 gas pair in PSF pure membrane and composite membranes containing 10 wt% and 20 wt% PEG10000 are calculated 26.57, 30.61, and 32.12, respectively.

This document defines the method to be used to determine the air permeability of curtain walling, both its fixed and openable parts. It describes how the specimen shall be tested under positive and negative air pressure. This document applies to any curtain walling product as defined in EN 13830. Air permeability was tested according to EN 14683:2019 and ISO 9237:1995 using an air permeability tester M021S (SDL Atlas, Rock Hill, SC, USA) with a head test area of 5 cm 2, and according to ISO 5636-3:2013 using an air permeability tester 266 (Lorentzen & Wettre, Stockholm, Sweden). Eight different commercially available disposable face .

The air permeability of hydroentangled nonwovens was tested according to GB/T5453–1997 standard test method by air permeability testing apparatus (YG461H, Ningbo . and the water pressure rising rate was 5 kPa/min. The moisture permeabilities of PBAT/hemp composite membranes and PBAT/hemp@SiO 2-PVSQ composite membranes were .

Comparison of Air Permeability Test Results. The results of fabric air permeability are closely related to the testing methods used. Among the test results obtained by four different testing methods, namely, ISO 9237, GB/T 5453, ASTM D 737 and JIS L 1096: the air permeability tested by GB/T 5453 and ISO 9237 are the same; the air permeability .

air tightness testing equipment

WEB17 de out. de 2023 · 278.1K me gusta,744 comentarios.Video de TikTok de MEGA FULL (@megafullx): «#megafullx #diosdega #degadios».martina catini. sonido original - MEGA FULL.

air permeability test composite|air permeability test for fabric